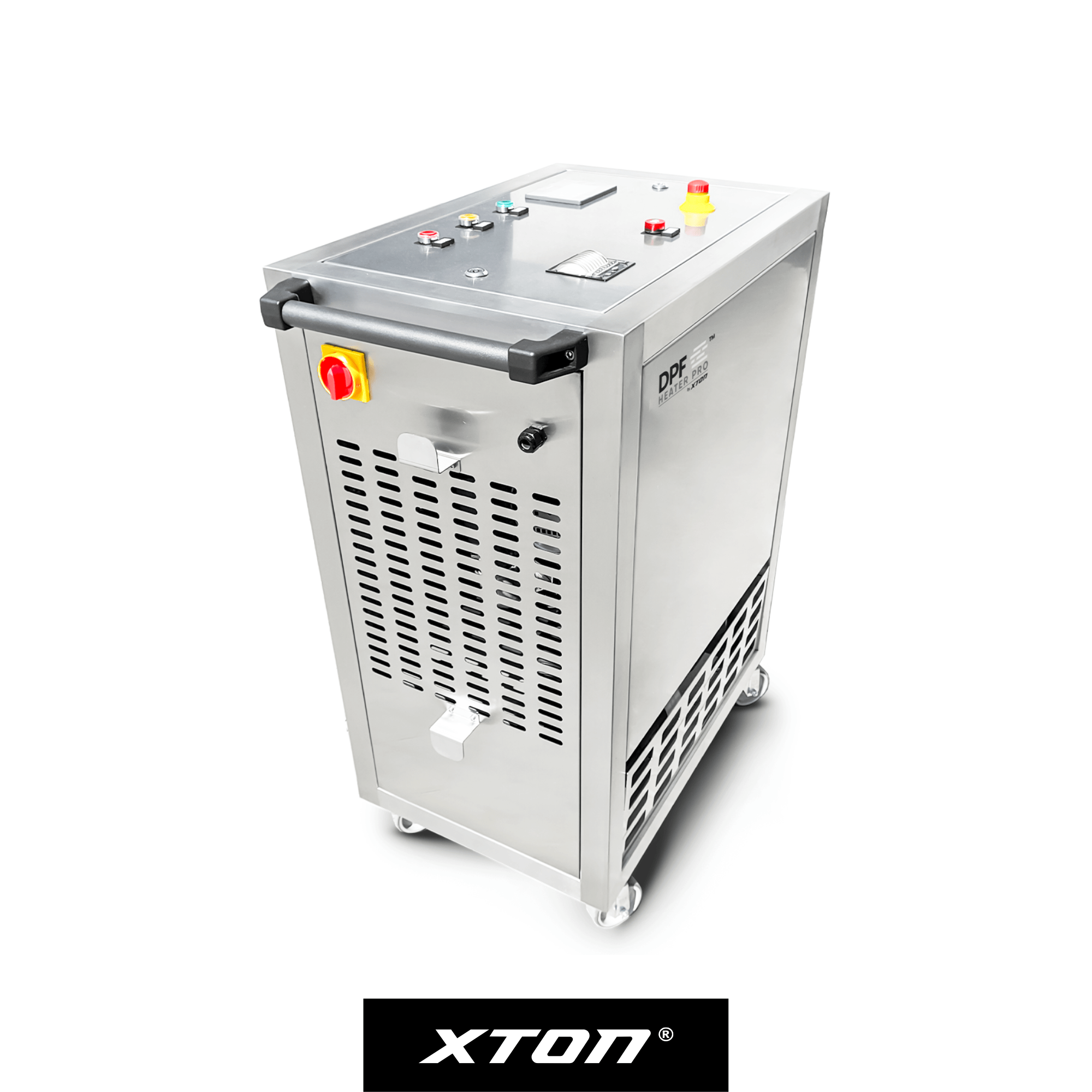

Description

Dedicated to drying all types of particulate filters and catalytic converters, the unit is made entirely of AISI 304 stainless steel and AISI 316 acid-resistant steel. It has an integrated measuring system and allows drying at temperatures of up to 130 degrees C using a side-channel turbine. A built-in thermal printer allows contamination measurements to be printed out. The device will work perfectly as an additional option for a particulate filter cleaning machine that does not have an integrated drying system.

BENEFITS OF USING THE DPF HEATER PRO:

- operation independent of the regeneration machine

- optimisation of the filter regeneration process

- low drying costs

- quality confirmed by a printout of the obtained parameters

- quick-action filter fastening system – Camlock

- adapters for trucks

- full automation of the drying process

TECHNICAL PARAMETERS

- weight 100 kg

- dimensions in mm (W/H/D) 920 x 1140 x 510

- air flow 390 m3/h

- overpressure up to 670 mbar

- supply voltage 3x400V

- maximum power 7.5 kW

- drying temperature from 70° C to 130° C

- integrated measuring system